INM GEN IO

EXPLANATION:

With the direct mounting structure of the motor, the external control panel can be closed and the smaller and smaller design can be achieved.

LCD display open pressure value, frequency, current value and set pressure value can be read.

Easy to program.

With the preparation of multi-pump system, 5 pumps can work together without connecting a control unit.

Setting the system set to be held constant The LCD screen can be adjusted.

Mod-bus communication protocol can communicate with outdoor units (building automation system, etc.).

Error screen display error.

Frost protection with antifreeze.

Manual or automatic operation.

Protected against high pressure and low pressure.

There are 3 different types of password protection available in the system.

In multi-pump systems, the faulty pump is deactivated and the backup pump is automatically switched on automatically.

Multi-pump systems feature the ability to move.

The process adjustment characteristic can be set by changing the PID.

The system automatically switches to sleep without cleaning the liquid.

The lack of remote water pumps has a dry running protection feature.

It can be used against over current, over voltage and phase loss.

The working hours of the pumps can be recorded and monitored.

Programmable relay output is available.

There are 6 digital input terminals which can be programmed.

TECHNICIAL SPECIFICATIONS :

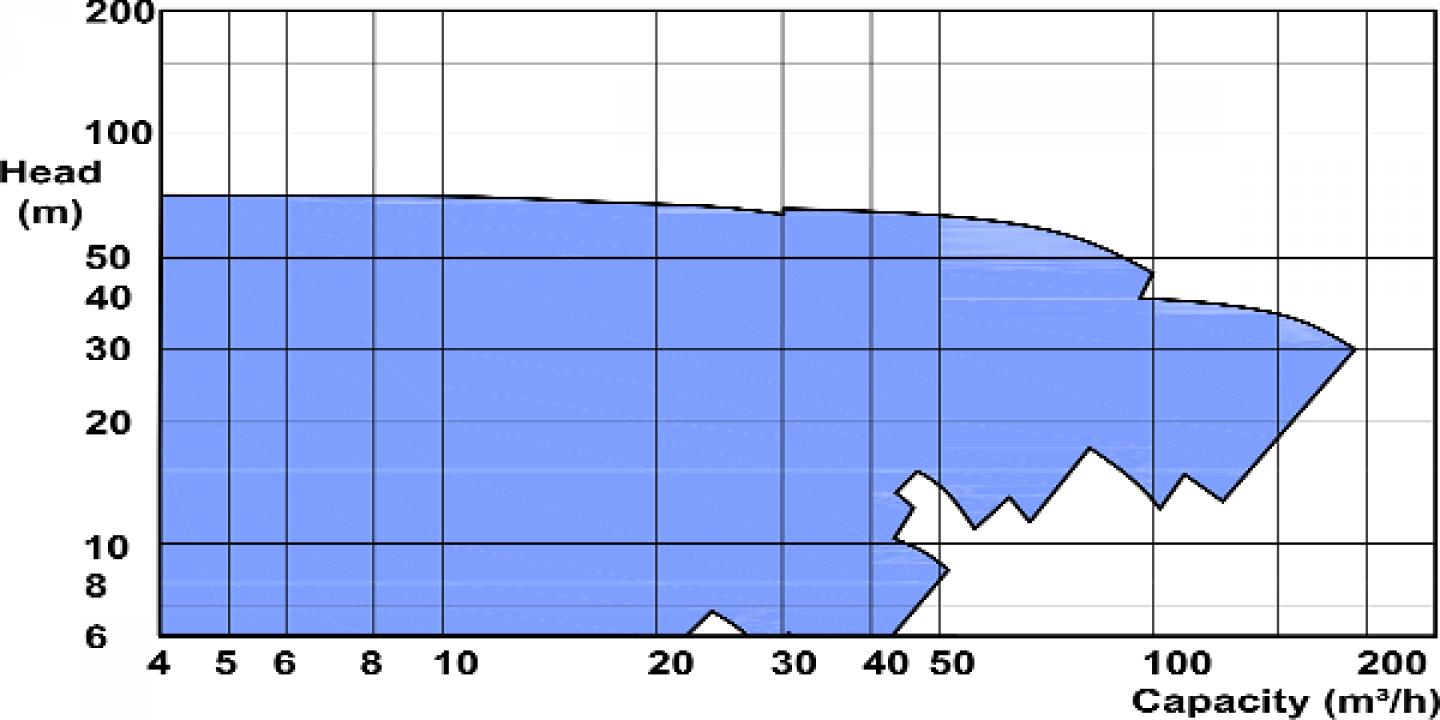

Flow Range (m³ / h): 10-530 m³ / h

Manometric Height Range (m): 3,5-95 m

Operating Pressure (bar): 10

Operating Temperature (° C): -25..120 ° C

Motor Speed Range (d / d): Frequency Inverter

Pressure Flange: DN40 to DN200 (PN 16) (DIN 2535)