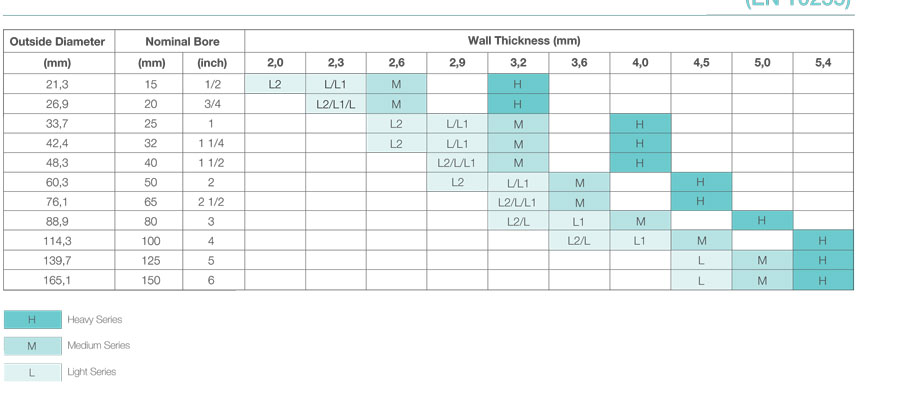

• Outside Diameter

21,3 mm - 339,7 mm

• Wall Thickness

2,00 mm - 12,7 mm

• Length

OD 21,3 mm - 101,6 mm; max. 7,50 m

OD 114,3 mm - 339,7 mm; max. 18,30 m

Transmission of liquids

• Production Norms

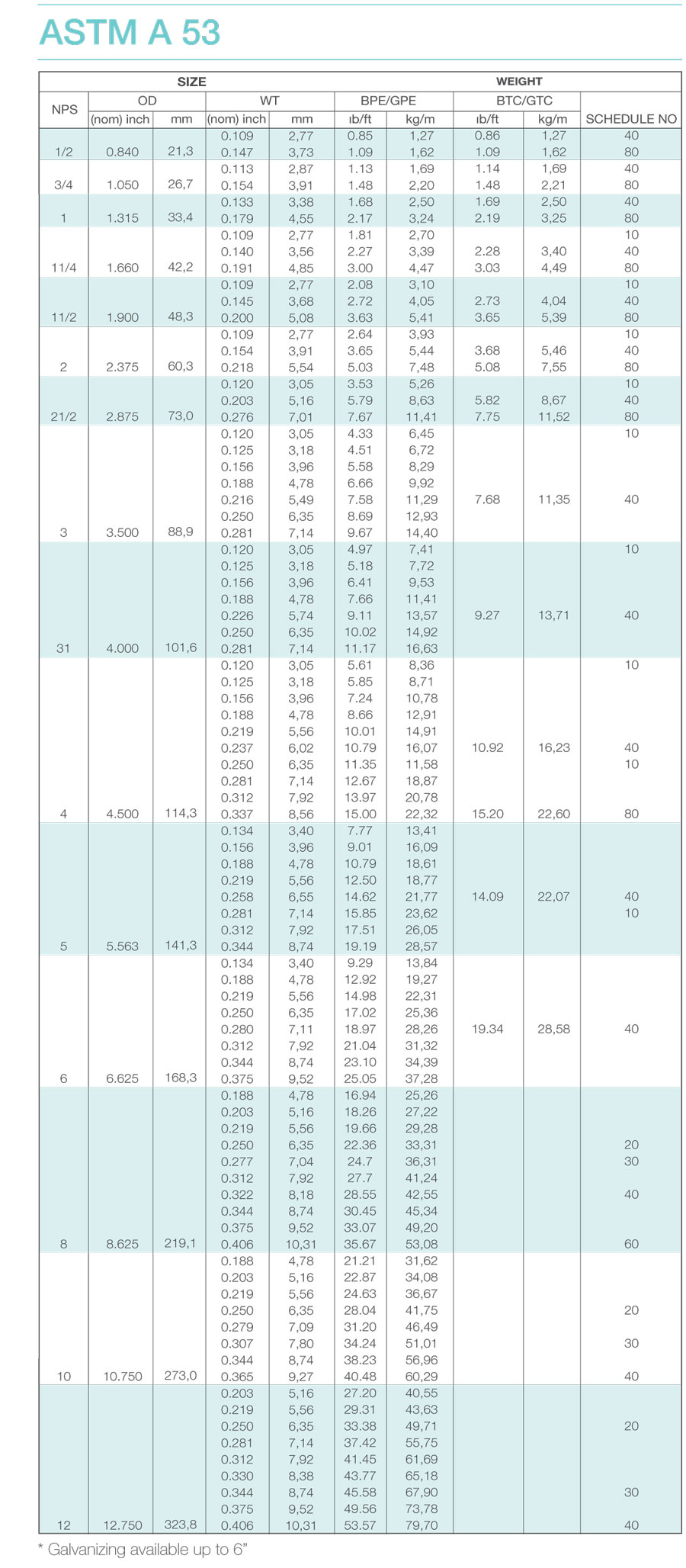

EN 10224, EN 10255, ISO 65, ASTM A 53, ASTM A 795, ASTM A 589

• Galvanizing Norms

EN 10240, EN ISO 1461 (BS 729), ASTM A 53, NFA 49-700, UNI 5745

• Production Standard For Threading and Coupling (1/2’’-6’’)

ISO 7/1, ANSI B.1.20.1, EN 10255

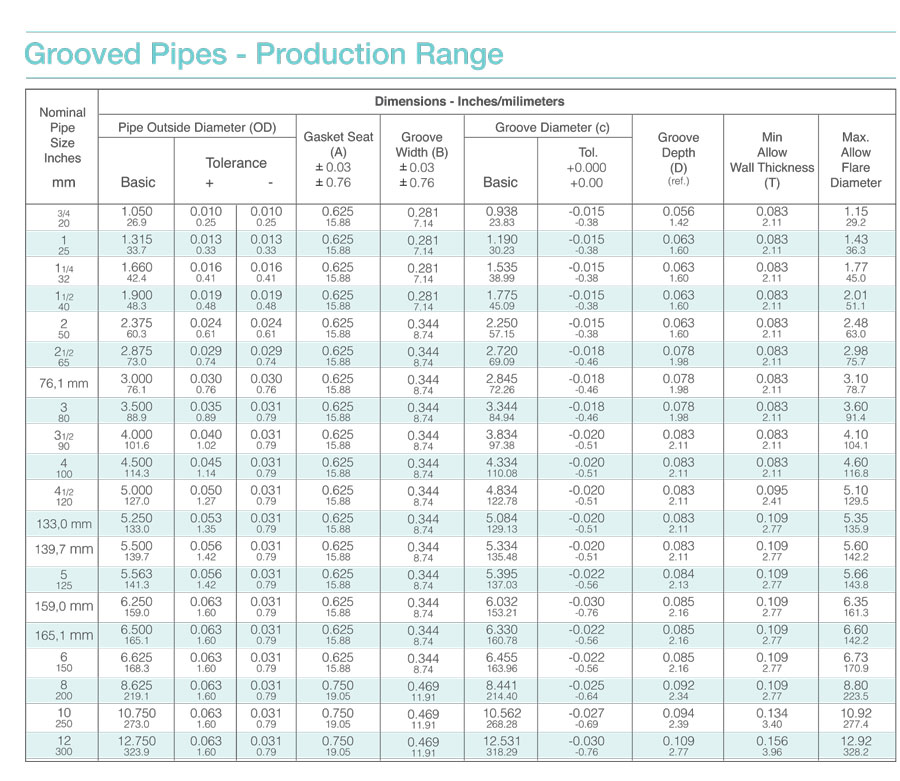

• Grooving (3/4’’-12’’) according to Victaulic Standard.

• Our Medium Series Pipes can be used up to 25 bar

operating pressure for water.

• Material Qualities

DIN 17100 St 37, St 44, St 52

EN 10025 S 195, S 235, S 275, S 355

Gr A, Gr B

• Visual and Dimensional Inspection

• Leak tightness testing: Hydrostatic Test, Eddy Current Test

• Destructive Tests: Flattening, Bending

• Mechanical Tests

• Chemical Analysis

• Metallographic Examination

• Others as required by the standards

• Ultrasonic weld seam test for gas pipes

• Mill Test Certificates

- Issued upon request according to EN 10204 2.1; 2.2; 3.1; 3.2

• NDT Standards:

- E/C (EN ISO 10893-1), E/C (ASTM E309)

• Plain end (square cut or bevelled)

• Threaded and coupled (Max OD: 168.3 mm)

• Grooved

• Outside protective coating (oil, varnish, epoxy)

(Other colors are available upon request.)

• Hot dip galvanizing

• PE, PP Coating

• Bare Pipe (Uncoated)